After talking to dozens of project managers and engineers who focus on physical products about agile, we have discovered a common theme. Most have heard of agile methods, but they often associate it completely with software development and can’t see clearly how agile can be applied to hardware. Typical questions arise, such as; “Do we really need to do daily standups?”, “Do we really need to break tasks into two-week (or less) sprints?”, “Are we expected to develop full working prototypes every sprint?”, etc.

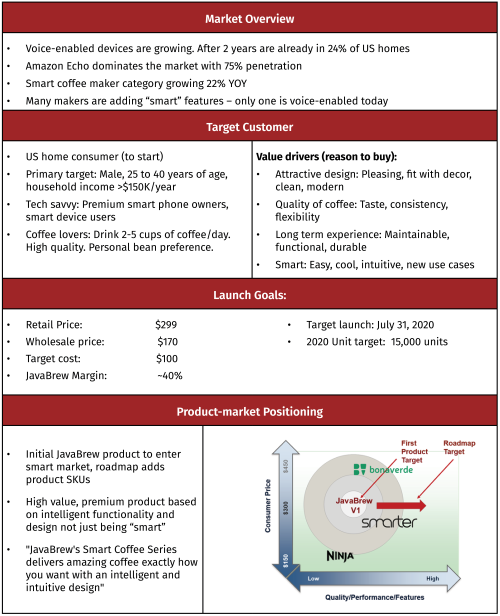

To help developers of hardware visualize how an agile project can be implemented using the Modified Agile for Hardware Development (MAHD) Framework, we have developed a 9-sept guide to Agile for Hardware that walks a practitioner through the whole process and answers these questions. The product we’ll focus on is a next-generation, cutting edge coffee maker. While this may not be as complex as many of the products you are developing, we think it provides a good example of how hardware, electronics, software, industrial design, manufacturing considerations and all other aspects of hardware development can get the benefits of agile thinking.

Step 1 starts before the project begins as Lynda, the product manager for the new “smart” coffee maker, prepares for agile success. Every three weeks we’ll release a new step until the product is released into manufacturing and on to the market. Each step will discuss the rationale behind the process, along with specific team activities and templates to execute the MAHD Framework. While we’ll use many agile terms such as “user stories”, “iterations” and “backlog,” these will be refined for how they relate to hardware, and more specifically, how you can apply them to your projects. Between steps, we’ll also share tips for how you might be successful with agile. In addition to posting here on LinkedIn, we’ll also post each step and tip on the AgileForHardware.org website where you can see the progress and catch up on past steps. We hope you join us on this MAHD journey.